Quality

“We are committed to exceed customer expectations, by continuously improving the quality of our people, products, processes and relationships.”

-Nammo Composite Solutions Quality Policy

Nammo Composite Solutions employs a full suite of techniques to ensure that all customer requirements are achieved for products ordered. These techniques include:

- Portable Coordinate Measuring Machines (CMM): Multiple CMM arms are used to verify dimensional requirements of components and assemblies. These mobile CMM arms provide the flexibility to conduct on-site measurements, allowing inspections to take place during in-process verification points, or as a final inspection. The company’s equipment uses both touch probe and laser scanning head attachments. Both Verisurf and PC-DMIS are utilized as metrology software for dimensional analysis.

- Non-Destructive Inspection (NDI): Nammo Composite Solutions employs handheld ultrasonic A-scan techniques to validate laminate and bond line integrity. This technique can inspect for voids, delaminations, or other irregularities in the structure. The company has experience in the development of both inspection processes and defect standards.

- Material, Coupon, and Component Testing: The material test lab at Nammo Composite Solutions is used to verify various mechanical and physical characteristics of incoming materials and parts produced. The company has a load frame to simulate tension, compression, and bending loads for proof and failure testing. Coupon level testing is also conducted on component tag ends to verify accurate processing, and typically consists of tensile, flexural, or short beam shear tests. Hydrotesting is frequently used to verify structural integrity and zero-leak conditions for pressure vessels. Nammo Composite Solutions also has an in-house lab for acid digestion of specimens to accurately measure fiber, resin, and void volume of laminates.

- Asset Calibration and Tracking: All tooling and measurement equipment (MTE) is catalogued within an asset tracking database that recalls calibration status, requirements, and frequency. An experienced compliance and metrology team inspect tooling and gauges to verify they are sufficiently accurate and fit for use within the production environment.

Documents

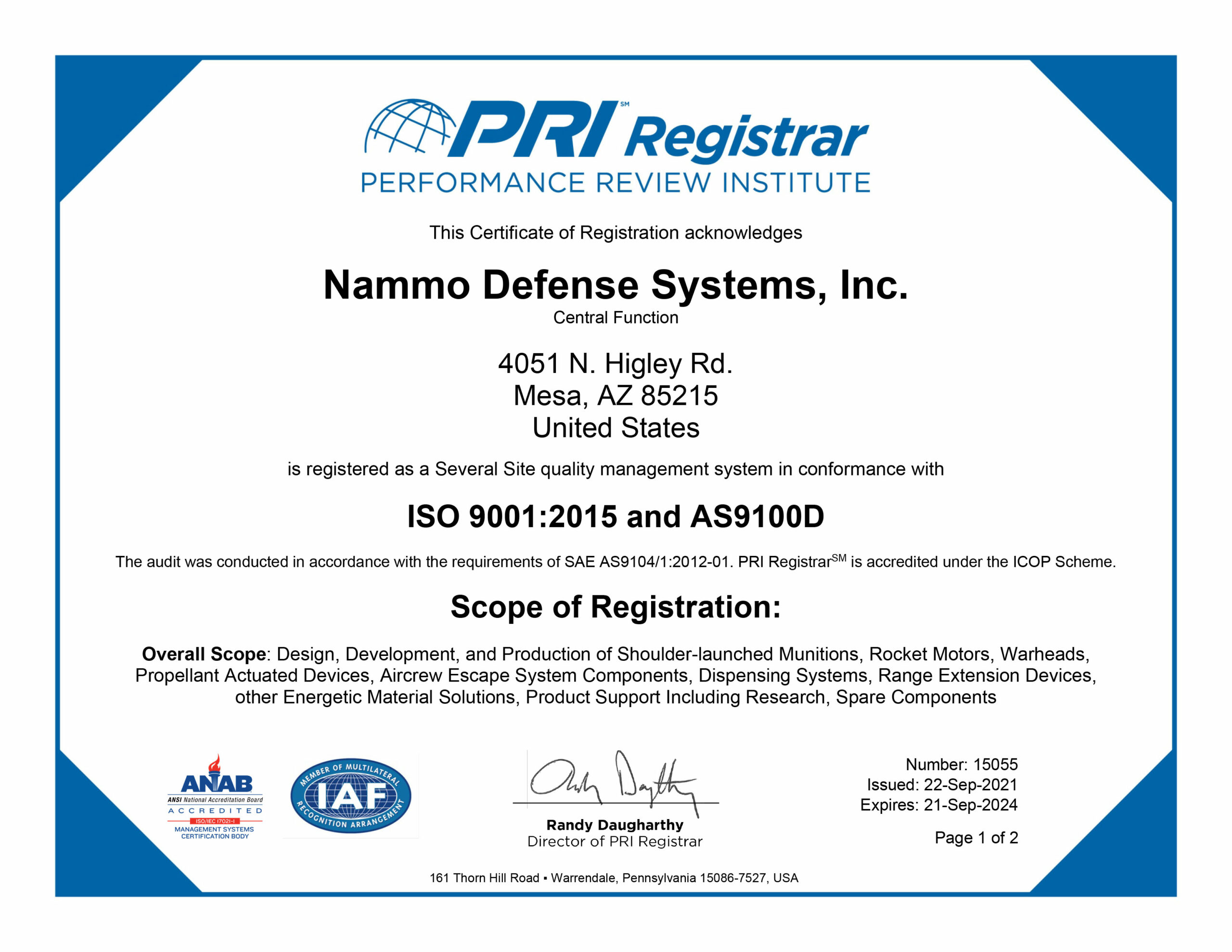

AS9100D Certificate